ReCycleBlaster

ReCycleBlaster

Closed Circuit Sandblasting

Closed Circuit Sandblasting

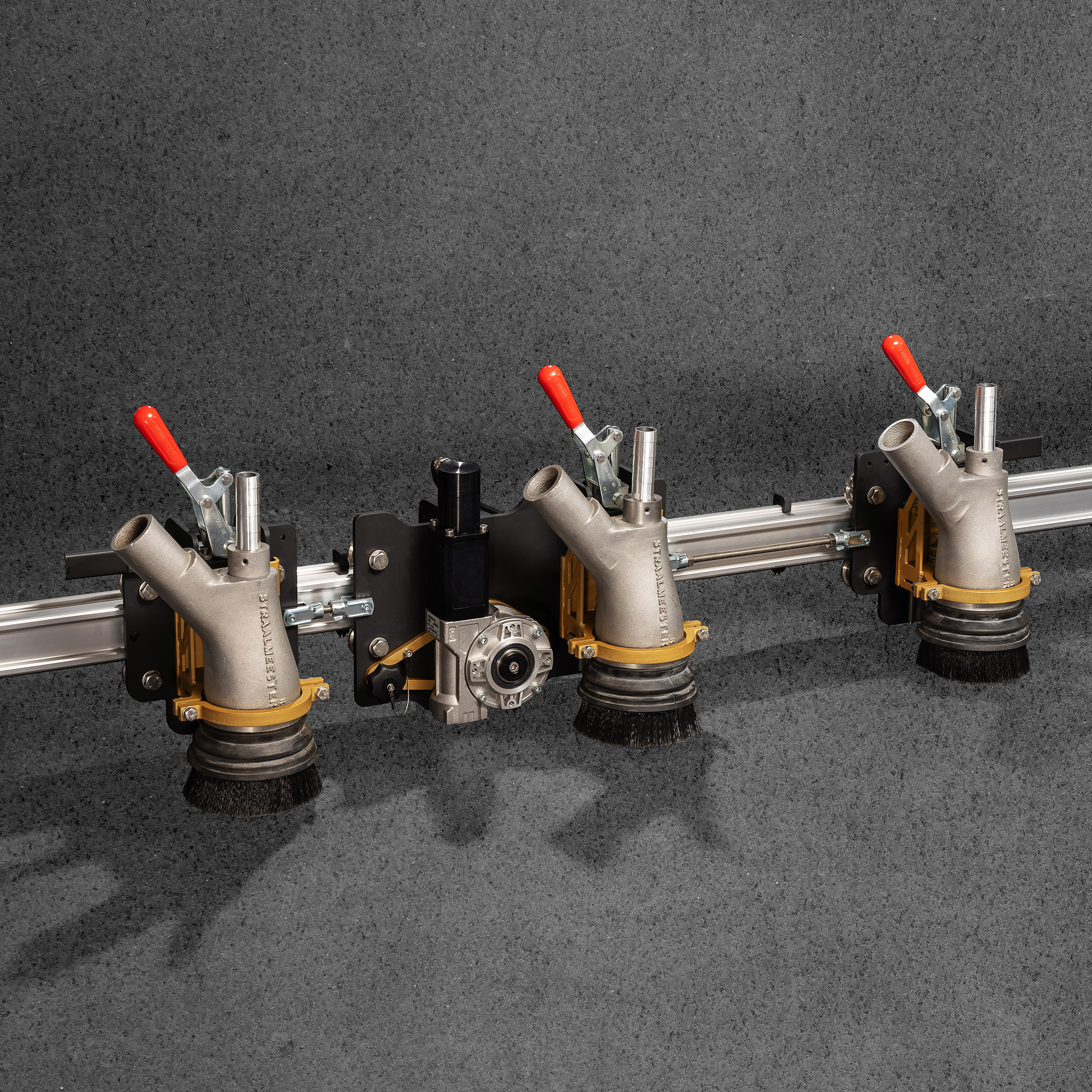

The MagTrack ReCycleBlaster is an add-on tool installed in front of the 4-wheel carrier for “closed-circuit” vacuum blasting. It uses high-pressure compressed air mixed with abrasive material to remove contaminants, coatings, rust, and other undesired materials.

The vacuum system collects and recovers the used abrasive and debris, separating contaminants and dust. The cleaned abrasive is reintroduced into the blasting process.

This makes the ReCycleBlaster ideal for industrial cleaning and preparation, establishing surface roughness without releasing harmful airborne particles. It reduces environmental impact, ensures a safer work environment, and is cost-effective by recycling abrasive material.

Modular design

Features

Features

- 3 nozzles

- Cleaning path: 2000 mm

- Dimensions: 2000x300x300 mm

- Weight: 35kg